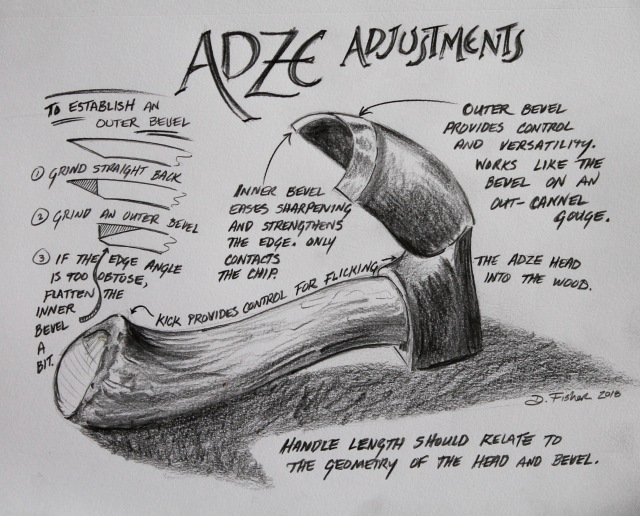

I’ve been getting a lot of good questions from people that, unable to find a good bowl adze, wish to make the most out of a less-than-ideal adze or refurbish an antique adze head. I’ve written about adzes in several posts, but I thought it would be helpful to pull some ideas together here in this post. With that in mind, I sketched some ideas above based on the first adze I bought over fifteen years ago, made by Pfeil, that I’ve reworked.

Here are some references that might also help if you’re looking to adjust or tune your adze:

- Although one adze is versatile enough to many different things, there is no one perfect adze head shape, inner/outer bevel relationship, or set of angles. Having a general understanding of how adze geometry and bevels work allows you to determine what will work best for you. Although far from comprehensive, This post should help, and there is a lot of good information in the comment section as well.

- In the sketch above, I have a simple diagram on grinding a new bevel. It can involve a lot of work, which requires patience and frequent cooling of the edge. To grind the outer bevel, I would essentially use the same technique for grinding a gouge bevel described in this post. And once the grinding is done, this post shows how I go about honing the edge of an adze.

- Some more good news: Blacksmith Jason Lonon plans to focus on lots of adze production this year, so hang in there.

- There’s other stuff about adzes on the blog here. Check under the “adze” category to the right.

Dave,

Thanks so much for sharing your knowledge. I’m currently working on a pfeil bevel edge and making a handle. I will study your drawings and read all these post to make the best of this attempt. Don’t have hickory stock so trying to use ash for the handle. First attempt ended with the handle splitting when I put in a metal wedge.

LikeLike

The ash should work well, Eddie. In fact, it’s what HK uses for their adze handles I think. On short handles like this, many good hardwoods will do the job. I made the handle of my HK adze from oak and it has been serving well for years. On longer handles as for felling axes and the like, the toughness of hickory becomes more important. On your next attempt at fitting the handle, sneak up on a really tight fit before the wedges (wood or steel) come into play. If the handle is really tight in the eye all around a split will be less likely. Of course, it may have been and stuff just happens sometimes! Also, make sure the handle is absolutely bone dry before you do the final fitting. Use a little kiln, or leave it by the woodstove, or something. You don’t want it to shrink at all after the fitting.

LikeLike

Thanks David!

A ton of good info., you love the lead pencil like I do! Great illustration.

JReed

LikeLike

There is a good maker up here in Toronto Canada.

http://www.torontoblacksmith.com/new-products/

LikeLike

Hi Dave,

Recently I bought an adze from small maker in KY. Seems pretty decent but now I have been trying to cut a trough to follow to the bottom of the bowl like you have shown, it goes ok for the first few strokes and then I srart having some trouble to get it to bite. I tried to measure the bevel angle and it seems to be about 35 Deg. Wonder if the trouble might be the angle is to much and the back of the adze hits before the edge, or suppose it could be operator error! Thinking of trying to change the angle to 25 Deg, thinking the edge would bite before the back of the adze would hit, but l’m a bit nervous of trying to change bevel if it’s not really necessary. Do you have any thoughts on this?

Thanks

LikeLike

I would make sure the bevel is not too rounded before grinding the bevel back. Rounding, especially abrupt rounding just before the cutting edge is the most common problem when an adze isn’t biting effectively.

Depending on how tight the curve is across the midline of the bowl, some adzes may not be able to negotiate it. So it may simply be that. However, a steeper outer bevel actually helps in that regard, although it doesn’t cut as sweetly in more open shallow forms. Rather than regrinding the adze, you can also easily cut that final cross-trench with a bent gouge once most of the bulk is out of the hollow.

LikeLike

My son made an adz for me last year. It is a right handed model in that the head is twisted so the cutting edge is about 15 degrees out. I have done the same thing by mounting a carving gouge. when the adze showed up, I could not get a good cut with it as he had ground a small (3/4″) radius on the out side edge which interfered with landing the cutting edge. I reworked the outside to about a 6 inch radius. The inside is beveled at about 20 degrees. Cuts fine.

LikeLike

Pingback: Long Handled Adze | David Fisher, Carving Explorations