I have some general information on tool selection here at my website, but I’d like to focus more specifically on the adze in this post. It is probably the single most expensive tool used for this work, so it pays to choose wisely. After all, your grandchildren might be using it someday. I only know two adzes well, but they’ve taught me some things about adze design.

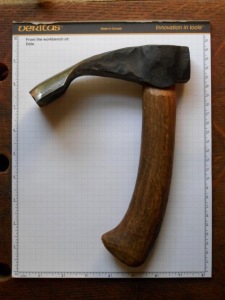

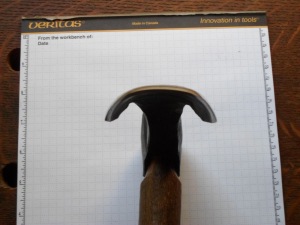

I’ll start by showing some photos of the adze I use the majority of the time. The adze head is made by Hans Karlsson in Sweden. The Karlsson’s have a small family forge in Sweden that makes excellent tools. They are designed well, with much consideration for how they will be used. Mine was purchased years ago through Drew Langsner’s online Country Workshops store. It is marked H-161 there. As far as I can tell, it is the same one available from these suppliers based in the U.K.: Woodsmith and Woodland Craft Supplies. They have other adzes there of various sizes made by HK and other good makers.

My HK adze arrived sharp and ready to go (except for the lack of a handle, but that was my choice). It has an outer bevel that is maybe declined eight to ten degrees from the line of the head. A shorter inner bevel strengthens the edge by making the total edge angle around thirty degrees. It enters the wood easily and the weight of the tool propels the edge through. The steel holds an edge under heavy blows, and sharpens easily. All I have done through many sharpening is to maintain it as it came.

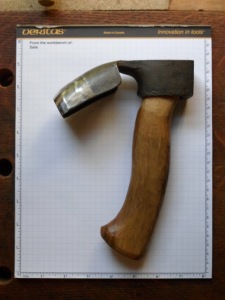

My other adze is a good example of how much work will be involved if you buy something poorly designed for bowl carving (even if the product description says “perfect for making bowls”). Before I had any idea what to buy, I purchased this adze made by Pfeil Swiss Made. Their carving gouges are excellent, but they missed the mark on the design of this tool.

My other adze is a good example of how much work will be involved if you buy something poorly designed for bowl carving (even if the product description says “perfect for making bowls”). Before I had any idea what to buy, I purchased this adze made by Pfeil Swiss Made. Their carving gouges are excellent, but they missed the mark on the design of this tool.

The handle is poorly designed in relation to the geometry of the head, and there is no outside bevel at all. It lacks the concentrated weight of the HK that helps propel the edge through the wood. It doesn’t arrive very sharp. In spite of all that, it will indeed remove wood from the hollow of a bowl; I carved some bowls with it. It took lots of tweaking to get it to work better.

After grinding away a lot of steel (carefully avoiding overheating) and adding a new handle, I now have a nice little adze perfect for tight hollows due to a combination of three factors: a tight sweep of the edge, a tight curve along the top of the adze, and a pronounced outer bevel (now). I guess you could say it has a tighter turning radius than the HK, but the HK provides a much smoother ride.

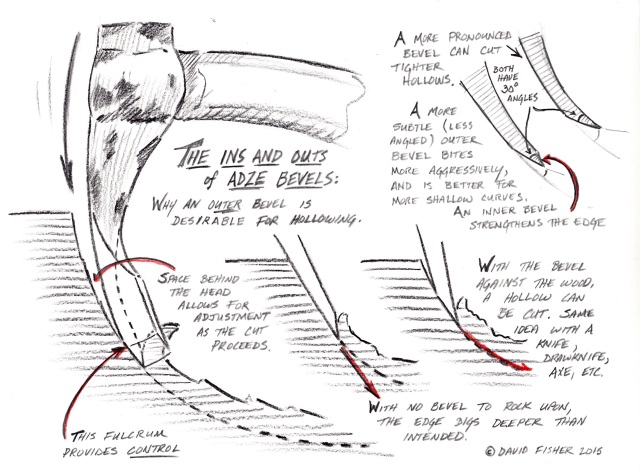

There may be some uses for which an adze with an outer bevel is undesirable. For hollowing bowls, you want some degree of outer bevel. I hope my drawing at the top offers some explanation as to why. Another way to think about it is like this: an adze is like a carving gouge on a stick. When used for carving work, gouges have outer bevels. They provide the carver with the freedom to control the course of the tool and come into, and out of, a hollow.

For bowl carving, outies are the best.

One last thought. If you can’t afford a good adze, but you want to start bowl carving, consider buying a gouge instead. Better to buy a good gouge than a bad adze. You’ll still need that gouge after you save enough for a good adze anyway. You can hog away wood pretty quickly with a large gouge and a mallet. I’d suggest something like a #7 sweep bent gouge (long bent) 25-35 mm wide. It might also be a good option if you don’t feel safe swinging an adze.

I also have the Hans Karlsson and Pfeil, which has been reground with an outer bevel for bowl carving. I prefer the HK, but had to wait 4 or 5 months for my order for the HK to arrive so started with a pfeil. I have not put a different handle on th pfeil yet which would make a big difference. What did you use for the Pfeil handle you made? Did you find a hatchet handle and carve it to fit?

LikeLike

Paul,

For my handles, I just split out a piece of firewood and shape it with a hatchet and drawknife. As it gets smaller I can see how it feels in my hand. These handles aren’t long like axe handles, so any harder wood will do. My HK handle is oak, the Pfeil is hickory. I originally made the Pfeil handle for something else (can’t remember), then adapted it. Just make sure the handle is bone dry before final fitting to the adze head.

LikeLiked by 1 person

Thank you. Great and helpful post.

LikeLike

Great information! Thanks for posting, it really helps us who are aspiring bowl carvers.

LikeLike

Pingback: Hollowing with an Adze | David Fisher, Carving Explorations

David, I am repeatedly awe-struck by the beauty of your bowls. Particularly the aesthetics of shape & proportion but also the finish and, sometimes, intricate decorative carving. The obvious point that had not struck me until I saw your sketches of the adze, above, is that you are a highly accomplished artist, as well as consummate craftsman.

I have so many questions but will make do thanking you for starting the blog & sharing you knowledge & experience. 😉

LikeLiked by 2 people

Pingback: The Great Adze Shortage of ’15 | David Fisher, Carving Explorations

Excellent post David,,, I have three adzes,,, a west coast Haida lipped adze (Innie),,, a Gutter adze (Innie) and a Grandsfors Bruk a Swedish adze (Outie) It came sharp yet needed a bit of tweaking to the inside bevel mostly ,,,

The explanation and illustration are spot on,,, The best part was the recommendation to use a large bent gouge if you don’t have easy access to these expensive tools,,, I made due with a large bent gouge for many years,,,I also used power attachments to my side grinder for many years for the roughing out,,, It worked,,, Yet I didn’t enjoy it as much as doing it all by hand let alone the safety issue, noise, etc,,, I think it is important to be making bowls by hand using just simple hand tools that did improve my skills as well,,, if i have to sweat a little it will improve my motivation to get efficient with my energy use,,, and made me come up with ways to make the process flow better thus making it a whole lot easier to justify the expenses of a good adze,,, The choice was obvious as you so well explained that an “OUTIE” works best for inside hollowing of bowls,,, For those exact reasons you explained

I would like to add that the Haida lipped adze is good for the outside hueing because it is an “INNIE” designed for convex or flat work,,, it is light and does take some practice to use efficiently ,,,It won’t replace my carving axe in the process ,,, It just gives me another way to get closer the final shaping of the outside of the bowl that i usually do with a double edged west Coast style knife rather than a gouge,,, but that would be a whole new post,,,

Thank you for making this so clear,,, Cheers HKL

LikeLike

HK 600g 5cm: I have a smaller HK adze than David I think, mine is the 600g 5cm diameter adze (although HK now also sell a tiny adze that is even smaller). It has both an outie & innie bevel, although I tend to think of it as primarily an outie. It works brilliantly well.

HK 700g: I make mainly large bowls, so sometimes think perhaps I should have got the 700g HK adze with the slightly wider, slightly flatten cutting edge as used by David. It seems designed for the sort of bowls I prefer to make. The extra mass is supposed to be insignificant in feel and would likely help hollowing larger, tougher blanks (e.g. oak) – and would likely balance the larger cutting edge. But instead I opted to buy a much larger adze by Czech manufacturer Narex (renowned for their chisels) for half the price:

Narex 2 handed adze: I bought one of these (http://www.amazon.co.uk/gp/product/B00JECU41K/ref=as_li_tl?ie=UTF8&camp=1634&creative=19450&creativeASIN=B00JECU41K&linkCode=as2&tag=various02-21). It is a pure outie and works brilliantly well – as an initial hollowing adze for large bowls, it is very fast & effective. It has a 7cm cutting diameter & supposedly weighs 1.5kg in total (I’d estimate the head to be about 900g-1000g). They are not currently manufactured as the Narex steel is notoriously hard to weld well, so they need to sort that out somehow – but there are still some available in shops & on the web (got mine from C.W. Tyzack (yes, that Tyzack! – at least it was). One of their smaller 1 handed adzes failed at the weld, according to an amazon.com review. Mine has signs of porous welds but not that much (being a larger tool probably helps); I got a former professional welder to look it over for me, he said not to worry, it is a common problem and as long as there isn’t too much it is fine. I’ve made 2 bowls with it so far and it makes me smile when I use it 🙂

LikeLike

UPDATE: I recently broke my handy 2015 Narex adze at the (porous) weld while hollowing a bowl! 😦 Fortunately Narex were cool about it. They knew there was a problem in the original model, fixed it in their production process in 2016 – issuing both of their fixed adzes with new product numbers – and are sending me a replacement, which is due to arrive today 🙂 So hopefully I can finish hollowing my big ash bowl this weekend.

BTW Re. the great adze shortage of 2015, I think it still continues.

LikeLike

BTW I held the small Gransfors Bruks adze a few years ago. It is more expensive than the HK adzes but comes with a good leather edge guard. The head is about 800-1000g; significantly larger & heavier than my 600g HK adze. For big bowls, that mass probably helps but that is a lot of mass to hold in one hand, even if you support your wrist with the other hand. Probably not ideal for the small & lightly built.

The Narex adze is of similar or greater mass than the Gransfors Bruks adze but with the longer handle makes for less strain – although I often end up using it choked up & one handed (the handle is very big near the head – so not ideal). I suppose I could one day fit a short handle (as Wille Sunqvist appears to have done with his large, re-steeled, favorite adze) or shave the handle near the head.

Of course, Gransfor Bruks also make (what I am sure are wonderful) large, 2 handed gutter adzes too – for 3x the price of the Narex. HK also make a slightly larger 2 handed adze (800g head I think) – which might be ideal for bowl making, certainly Countryworkshops in N.Carolina used to recommend it (& probably still do) over the smaller single handed adzes.

With a 2-handed adze, some kind of low-bench is required/advisable. I use my chopping block with a big old tire screwed on top, Norwegian-style. But when using a 1-handed adze, I use my comfortably high Robin Wood “Bowlmate”, with opposing wedges to keep the blank secure.With either I walk around the blank and work from different positions.

LikeLike

FYI I ended up buying a very cool, medium sized Ukrainian made adze on Etsy a few years back (pre-war). As I haven’t taken to the newer, stronger big Narex adze, I preferred the shape of the older, weaker original adze.

The HK is still my main adze but I’m hoping and expecting the Ukrainian adze more in the future. (I wonder what happened to the wonderful makers and their workshop and steelworks 😦 ).

LikeLike

Pingback: Jason Lonon | David Fisher, Carving Explorations

Pingback: Sharpening an Adze | David Fisher, Carving Explorations

Thank you. I study many thing in this article about adze and sharpening.

Yesterday, i look for proper adze for bowl carving.

And i found adze with inner bevel!

so, i thought it was strange.

May be, it makes adze deeply embedded in wood.

Now, i can confirm my thought through your article.

May be, i think i will come to your blog very often^^

thank you

(and, if you don’t mind, can i use your sketch at top of the article??)

LikeLike

I’m glad you found the article helpful. Thank you for your comment. You are welcome to use the sketch, but please just for your personal use — not for profit.

LikeLike

Thank you for your warm hospitality.^^

LikeLike

Love your illustrations. They remind me of Eric Sloane. Highest praise I know of

LikeLiked by 1 person

That is high praise, indeed, Brian. Thank you very much. If I can even come close to Eric Sloane one day, I’ll be thrilled. I do enjoy it.

LikeLike

Hi Dave, Thank you so much for this amazing resource. What a gift you give to the world. Could you write a blog or explain in more detail about how to handle an adze, the bevel angle in relation to the handle and pivot point?

LikeLike

Good suggestion. I’ll plan on getting together a blog post on that sometime. Meanwhile, the general idea is to think about the pivot point around which the head will rotate and what that means for how the cutting edge will enter the wood. If you rest the cutting edge on a workbench and extend the pivot point of the handle to the edge of the workbench (with the heal of the handle extending just off the bench), the cutting edge should be directed, generally, at 90 degrees to the workbench surface. A common problem is for handles to be too long or shaped incorrectly to mesh with the geometry of the head. This often results in the outer bevel slamming into the wood when the tool is swung, thus an inefficient cut and sore wrists.

LikeLiked by 1 person

brilliant, thank you, ill try that. and just to clarify, the pivot point would be where you hold the tool?

LikeLike

Dave, long time listener, first time caller. I would be very interested in seeing a simple illustration of this thought on handles. I just received a new adze head from Black Bear Forge.

LikeLike

TJ — Here’s something to check out in the meantime: https://www.dictum.com/en/tools/woodworking-metalworking/sculpting-tools/adze It gives you the general idea. Some depends on how an individual uses a particular adze — that can make subtle changes to the location of the pivot point.

I don’t want to encourage paralysis by analysis, though. There’s a fine line. Get your tools working as best as you can — but most importantly, get them WORKING. A tool doesn’t have to be absolutely perfect to do great work and enjoy it.

LikeLike

Thank you very much for the link and the encouragement (even if I didn’t see it until now , oops). I had initially experienced the slamming effect you mentioned above but your advice and a new handle proved to be quite helpful. Thank you for all the knowledge you freely share with the community and your work is quite an inspiration for many of us.

LikeLiked by 1 person

Well, in general, yes, but it depends a bit on how the particular adze is swung — or meant to be swung. In the case of my one-handed hollowing adze, the tool is flicked into the wood, pivoting off the lowest finger on the handle, so where that lowest finger sits is the pivot point.

LikeLiked by 1 person

ok thats clear thank you, ill see how i get on

LikeLike

I know your Youtube-channel for quite a while now and it was always a pleasure to watch your videos. Now I am starting into green woodworking myself. I will start with spoons and maybe some kuksas, but having seen your videos, I also want to give bowls a try. Searching for tools that are not so expansive, I stumbled upon some cheaper adzes, which seemed to be great on the first view. But they are innies and now I know, why I stopped and didn’t buy them (it was just a feeling that innies may not be ideal for bowls).

This article and your finewoodworking-video about axes and adzes helped me a lot.

Long story short:

Thanks a lot for all your inspiring videos, for sharing your experiences and your knowledge!

All the best to you and your family!

Uwe

LikeLiked by 1 person

Thanks, Uwe! Very kind of you to say so. Glad the information was helpful. Happy carving!

LikeLike

Innie for across the grain. Outie for with the grain. Bothie for general use.

LikeLiked by 1 person

I would add that all my adzes have a lengthwise curve which leaves me with a an innie bevel. My son made an adze in this manner but rolled the edge of the curve at 3/8′ from the edge which caused the blade to bounce out. I reworked the blade with a 10″ radius from about 2″ behind the edge. Works like a charm now, as I do most of my cutting across the grain. I generally use a gouge to work with the grain.

As to sharpening- I have found that an innie edge is well shaped if the plane of the bevel intercepts the center of the mass of the head. To do this, I have used an 8″ X 1″ dowel tapered from 3″ to about 1/2″ with a steel pin protruding. The dowel is wrapped with sanding belt material. Where the handle enters the head, I put a small hole to receive the pin. Wiping the dowel from side to side shapes and sharpens the bevel and gives more satisfactory results. I used this method on other adzes that were not shaped to this angle and the cut was improved in every case.

LikeLike

Pingback: Adze Adjustments | David Fisher, Carving Explorations

Hi David,

did you notice that the experts at dictum.com (https://www.dictum.com/de/adze) are saying the exact opposite of what you are stating with regard to the bevels? Outer bevl: “Material can only be removed with additional hoeing movements”.

I find this quite confusing since you also recommended this site for additional information…

Max

LikeLike

I would agree that when an outside bevel is too strong it can interfere, such as when cutting a gradual shallow hollow. I reference this idea a bit in the top right of the diagram. They express things a little differently there, but the general principles are the same.

There are so many variables in the way an adze is used that rules only go so far, but I think in general for most bowl hollowing some outer bevel makes more sense. The versatility and practicality of an outer bevel can obviously be seen in carving gouges which generally have outer bevels. The fulcrum effect of the back of the bevel allows for control and adjustment.

LikeLike

Hi David,

just do add some more info:

http://www.ruengener.eu/fotos/mollenhauer/mollen3.html

this is a German site showing one of the last German “Mollenhauer” and his tools as well (no text needed). There is a collection of adzes among the pictures. Interestingly all of them have just a very short and straight handle. And they seem to have an inner bevel from what I can see – but I’m no expert by any means.

LikeLike

I love that film, Max. Those adze heads are quite curved, or drooped, from poll to edge. It seems that the would require a very short handle so that the tight rotation is in harmony with the head. If you put a long handle on that same head, it would just slam the forward part of the head against the wood when it was swung. The tight curve of the head also means that no outer bevel is needed — essentially, the back of the tool becomes one big bevel (which would be ideal in certain circumstances). If one is using this particular adze to make a similar design over and over, that works well. It lacks the versatility in use that an outer bevel provides. I’ve wondered about the width of those adzes. I’m not sure, but it seems to me that they would make sense for relatively soft woods but less so for harder woods. I’ve never tried one out like those however.

LikeLike

Hi David,

thank you for your detailed answer! I had to read it three times to fully understand what you were saying – thank you for taking the time!

I now feel somewhat motivated to buy a (not so expensive) adze and remodel it myself. the Narex adze got some good reviews but certainly needs a new handle. And then there is another adze from the Pfeil company you mentioned which as far as I can see has a more rounded shape and also weighs a lot more (900g) than your first Pfeil adze (https://www.bildhau.de/en/pfeil-sculptors-round-adze). But this one has a way to long handle and for sure also needs a new one. Have you ever written/sketched how to find the right adze handle length/shape for a given adze head? I just know it needs to have the exact right length to make the tip of blade hit the wood at about 90 degrees to make the most efficient cut. And it needs a “kick” to provide control for flicking. Is there something else I missed?

LikeLiked by 1 person

No problem, Max. Good questions. And my original answer was too long and detailed. After re-reading it, it was indeed confusing, so I’ve shortened it now and gotten more quickly to the point.

I have an article in process currently about a lot of this, including the relationship you’re asking about between the handle and the cutting edge. So more on that later, but you are correct in your description. See my reply to Alice above. You simply want the cutting edge to enter the wood sweetly when the tool is swung correctly and naturally.

LikeLike

Max, I have a large Narex adze. I would not recommend the current model for bowl carving. The original design had an excellent shape – much like a large Gransfors Bruks adze – and worked very well but it broke at a porous weld 😦 The replacement is stronger, having the weld diagonally across the handle eye but I don’t like the, much different, over-ground shape, it does not look right nor does it work right for my purposes (bowl carving) unfortunately 😦 – but perhaps it suits others? The handle is quite large diameter but I quite like that, not a problem for me, and there is enough wood that you could easily customize it yourself using a knife, spokeshave and/or card scraper (the smaller adze, which is perhaps more suitable for general bowl carving, has a different handle, no idea if that is large diameter).

Adzes are not all made equal though. I suggest that you get a proper, traditional, hand forged adze, not welded, cryogenically hardened adze. Made by a blacksmith who knows what they are doing specifically with respect to bowl carving adzes. As tools go, the adze has a hard life, so probably not really the place to economize. I have a Hans Karlsson adze, which is wonderful but it was expensive and, with current exchange rates, is now prohibitively expensive for most people in England now (and consequently nobody here had them in stock last time I looked). I bought a medium sized adze from the Ukraine via the Etsy craft website and it is outstandingly good, just beautifully made and finished and includes a high quality, hand-stitched leather edge guard and belt holster. Better than the more expensive Swedish adzes (the “Gold Standard)” in several ways. It cost almost exactly the same as my original 5cm HK gouge did several years ago – when exchange rates were much more favourable; not cheap but good value as it is superb. Actually the I think the cutting diameter is similar to my HK gouge (maybe 5 or 5.5cm?) but it has more weight in the head and a longer handle which make it useful for starting, especially on bigger bowls. I use both adzes. I expect some of the US blacksmith made adzes *might* offer the best value for money.

BTW Many/most English bowlmakers go for the 5cm/500g HK adzes, which I have. It works great, could be used by almost anyone and is versatile: large bowl, small bowls, kuksa, not a problem. But I think David’s larger (600g/7cm?) gouge is likely a better choice for the large bowls I prefer to make. Robin Wood commented that the two sizes are not significantly different if weight and feel, so perhaps not a big deal. I’m quite large and strong and I feel (actually I know) I can comfortably benefit from using a slightly larger, heavier adze for bigger bowls. 600g-700g seems like it would be ideal, for me anyway. Some of the less expensive adzes (from US and Bulgarian makers) seem a tad light to me. The 475g ones are probably fine but much less than that might only suit smaller people. You need a bit of welly! 😀

BTW I love the small number of Swedish tools I bought. It felt painfully expensive buying them some years ago but they are now as good as when new, perhaps even better, and have appreciated significantly in value, due to scarcity and exchange rates. I have explained to my son the value of these tools, in case anything happens to me, and was pleasantly surprised to hear that he might keep them rather than selling them. 🙂

LikeLike

There are more makers of adzes since this post was originally written over five years ago. I am not good at keeping up with new developments along those lines, but from what I can see — and from what I have heard from others with direct experience — many are very good. I’ll include some links to some makers and suppliers below, not as an endorsement necessarily, but rather just as some helpful possibilities as folks explore and search for adzes.

http://www.mainecoastcraft.com/tool-sales.html U.S. supplier

https://woodsmithexperience.co.uk/shop/category/adzes/ European supplier

http://www.klensmide.se/ Hans Karlsson’s site

http://www.djarv.se/djarvenglish/startsida.asp Svante Djarv

https://www.facebook.com/Ironramforge/ Iron Ram Forge

https://www.joshuaburrell.co.uk/product/50-mm-radius-hand-adze Josh Burrell

https://www.etsy.com/shop/kharkivforge Kharkiv Forge

https://jasonlonon.ecwid.com/#!/Adzes/c/21924202/offset=0&sort=normal Jason Lonon

http://www.sevenpinesforge.com/product-category/axes-hatchets/ Seven Pines Forge

http://www.kestreltool.com/adzes Kestrel Tools

https://www.northbayforge.com/adz.htm North Bay Forge

I have no plans on trying to keep up or own all of the adzes available, so if anyone wishes to add some additional helpful links for folks or add some helpful comments about the tools above, then please do so. Thanks!

LikeLike

Useful list of adze makers David, thank you. 🙂 It includes the Ukrainian maker I purchased from: https://www.etsy.com/shop/kharkivforge . Superb product quality. Good service too, easy and pleasant to deal with.

LikeLike

Hi everyone,

there is short explanation of adze bevels types and it purpose in EN, SE, RU DE languages 🙂

https://www.dictum.com/en/cat/index/sCategory/2682

LikeLike

Hi Dave,

I’ve recently purchased an adze from at Etsy maker. It has a pressure fit on the head where it can slide down toward your fingers. It came loose almost immediately and every time after when I swing and don’t get a bite. I’m not sure if there’s a way to set the handle? Since it’s tapered, I’m not sure a typical axe wedge would do it, but I’m thinking of trying. Is this just a design flaw that will never be good, or is there some way to make it work?

https://www.etsy.com/listing/684667712/curved-bowl-adze-woodworking-wood?ref=as_recently_viewed-2&pro=1

Thanks for your excellent posts and your knowledge sharing!

Ben

LikeLike

I took a look at the photos, Ben. That reverse taper handle attachment style (usually a square shape rather than oval, though) was often used in larger adzes designed for dressing timbers and such. But in those applications, the adze handle was usually pretty vertical with the head below, so gravity kept the head tight against the handle.

I would say an axe wedge alone will not fix your problem because there is no shoulder on the handle below the head to keep it from working it’s way down again. My initial thought is to pin the head to the handle, but that may weaken the cheeks of the head if you drill for a pin, and it still may wobble a bit over time. If you think the handle is beefy enough, you could drill through the handle just under the head and insert a pin.

I think I would possibly try to make a new handle that has a swelling/shoulder beneath the head (so the handle couldn’t move down, then I would use wood wedges to spread the wood open in the eye so that the head couldn’t move up, but it’s hard to say without having the tool present. I’d also cut off some of that excess wood above the head that could interfere as the head follows through the cut.

LikeLike

Thanks for your time and response, Dave. I almost sent it back but decided that maybe I could reshape the handle by moving the head up and using that excess wood above. I will see if I can get enough of a shoulder that way before I start from scratch. Again, I appreciate how you share your expertise and enthusiasm.

LikeLike

Hi, Dave. My name is Kyle, and I’ve been making spoons (and the occasional bowl) for almost two and half years. I just purchased the Narex 2″ bowl adze (a significant investment for me, as my day job consists of working at a grocery store), and I was wondering how you would go about getting it sharpened and ready for work. I’ve already read your article on sharpening adzes, but this one needs some work. Could you give me any tips?

LikeLike

Hi, Kyle. From the photos that I can see https://taytools.com/collections/brands-narex-green-woodworking/products/narex-small-adze-one-handed there seems to be a significant abrupt rounding near the cutting edge. This will tend to prevent the edge from entering the wood sweetly. You’ll be fighting that rounded bevel and it will jar your wrist every time it hits. There may be other improvements possible for this adze, but I would at least suggest flattening that bevel, which may take a lot of hand work or some grinding. I outline that procedure in a recent Fine Woodworking article https://davidffisher.com/2020/10/02/adze-article/. If you can’t find that issue for sale, many libraries will have it available for free. But these two posts also will give you the idea:

LikeLike

Have you heard of Joshua Burrell? I’ve noticed that quality adzes are very hard to come by, and I have an opportunity to buy his 5cm hand adze for a good price. Unfortunately, I am not finding much about him online. I’m hoping someone here would know whether or not he makes quality tools.

Many thanks!

LikeLike

Here’s a link to Josh’s website: https://www.joshuaburrell.co.uk/category/adze I met him at Spoonfest and he’s a nice guy. His adzes look good to me, but I didn’t have a chance to try one out.

LikeLike

This is very informative, thank you David. I’d like to order one of Hans Karlsson’s adze (when they are available) – which size do you suggest getting? Thank you

LikeLike

I prefer the 60mm adze for most of my more open bowls (dough bowl style). The 50mm has a more rounded edge shape and is ideal for bowls that are more steep and deep. You really can’t go wrong with either of those. The 50mm is a bit lighter too, so that is something to consider for those who may find a heavier adze uncomfortable to use.

LikeLiked by 1 person

Thank you very much, David, that is very helpful. Cheers! RC

LikeLike